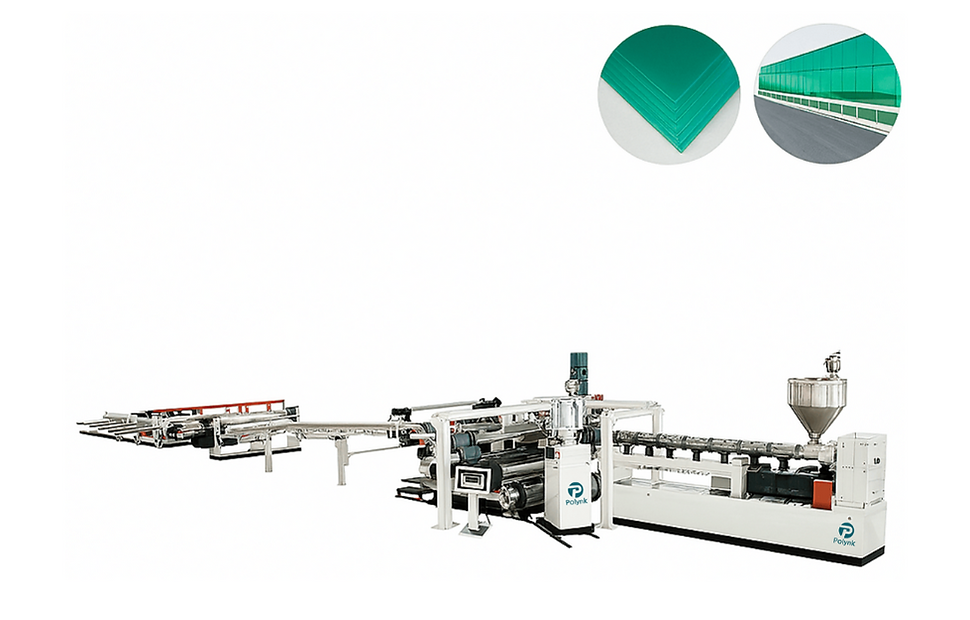

PC Solid / Corrugated Sheet Extrusion Line

Product Overview

OmegaPack, in partnership with Polynk (JWELL Group), offers a specialized extrusion line for producing PC (Polycarbonate) solid and corrugated sheets, widely used in architectural glazing, roofing, signage, and safety barrier applications. These sheets are valued for their high impact strength, UV resistance, and long-term weather durability, making them ideal for both industrial and civil infrastructure projects.

This extrusion system is equipped with precision melt control, advanced calendaring, and post-forming units to ensure dimensional stability and high optical performance across a wide temperature range.

Applications

PC Solid Sheets

Construction & Architecture

Used for commercial facades, curtain walls, partitions, and canopies in modern buildings.

Public Infrastructure

Ideal for telephone booths, sound barriers, and transparent partitions along highways and city roads.

Safety & Protection

Suitable for military and police riot shields, vehicle windshields (motorcycle, aircraft, train), and aviation containers.

Advertising & Display

Used for lightboxes, signage panels, and branded display stands in outdoor environments.

PC Corrugated Sheets

Industrial & Utility Roofing

Used in warehouses, temporary buildings, stations, lounges, swimming pool covers, and recreational shelters.

Cold & Hot Environment Zones

Stable performance between –40°C to +120°C, ideal for regions with harsh temperature fluctuations.

Key Benefits and Features

Feature | Description |

Extremely high impact strength — 250–300 times stronger than ordinary glass | Excellent light transmission, UV protection, and weather resistance |

Stable mechanical performance over wide temperature ranges | Flexible design options: flat solid sheets or wave-style corrugated profiles |

Lightweight, easy to cut, bend, and install | Resistant to yellowing, aging, and chemical exposure |

Process steps

Specifications

Specification | JW-130/38-2200 | JW120/38-1400 |

Material | PC | PC |

Products Width | 2100mm | 1300mm |

Products Thickness | 2-10mm | 1.5-10mm |

Extruder Specification | 130/38; 45/30 | 120/38 |

Capacity (Max.) | 550kg/h | 450kg/h |