High Polymer Composite Waterproof Roll Extrusion Line

Product Overview

OmegaPack, in partnership with Polynk (a JWELL Group subsidiary), offers a precision-engineered High Polymer Composite Waterproof Roll Extrusion Line designed for the production of advanced waterproofing membranes used in large-scale civil, industrial, and infrastructure projects. This system utilizes a multi-layer co-extrusion process, combining polymer materials such as PE, EVA, or TPO with reinforcement layers like polyester tire fabric or fiberglass mesh.

Built for durability, flexibility, and environmental resistance, the line supports a wide range of waterproof membrane applications with high tensile strength, excellent bond performance, and production efficiency.

Applications

Waterproofing membranes produced by this extrusion line are widely used in:

Roof Waterproofing

Long-lasting protection for residential, commercial, and industrial roofing systems.

Basement & Underground Structures

Acts as a robust barrier against water ingress in foundations, retaining walls, and basements.

Tunnels and Subterranean Infrastructure

Delivers structural sealing for subway systems, transportation tunnels, and water pipelines.

Bridges, Dams & Civil Engineering Projects

Provides strong anti-corrosion and moisture resistance under high stress and variable temperatures.

Green Roofs & Podium Slabs

Supports modern architectural applications with flexibility and low environmental impact.

Technical Highlights

Fully automated dosing and co-extrusion control

Anti-stick casting roller system

Online tempering to eliminate internal stress

Tension-regulated pulling and winding system for smooth operation

Customizable roll width and thickness based on project needs

Key Benefits and Features

Feature | Description |

Multi-layer membrane output with polymer base + reinforcement fabric | Compatible with PE, EVA, TPO, and other polymer blends |

Incorporates polyester, fiberglass, or custom scrim for structural reinforcement | High tensile strength, flexibility, and tear resistance |

Excellent performance under chemical exposure, UV radiation, and thermal cycling | Supports installation methods including hot melt, cold bonding, and mechanical fixing |

Designed for tight seam welding and efficient roll handling |

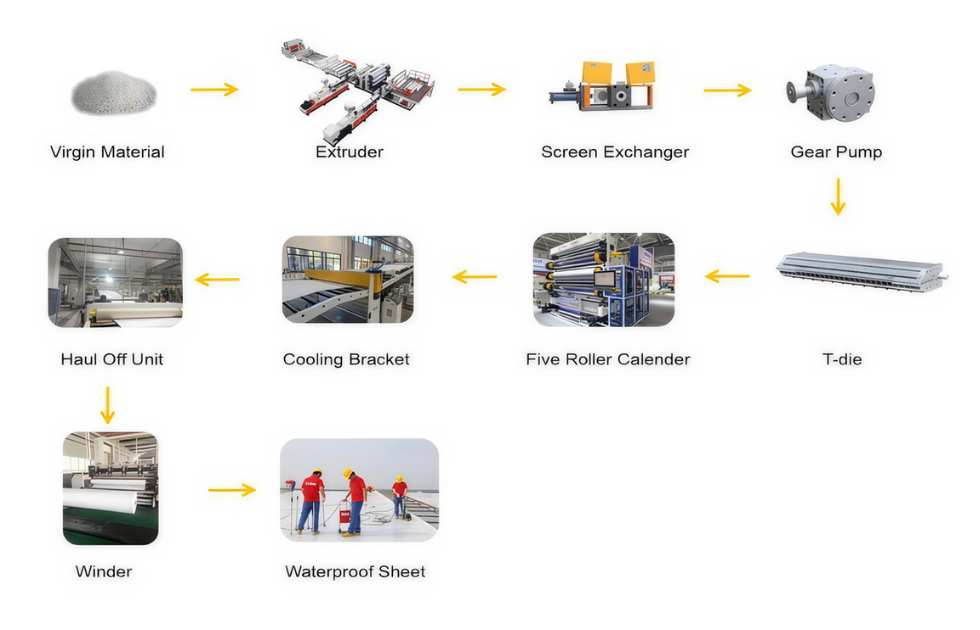

Process steps

Specifications

Specification | SJZ92/188-SJZ80/I56 | SJP130/36-SJZ92/I88 | JWS150—JWS120 |

Products width | 1200-2000mm | 2000mm | 2000mm |

Products thickness | 0.5-3.0mm | 0.5-3.0mm | 1-2mm |

Capacity | 800-900kg/h | 1200-1300kg/h | 1000-1100kg/h |