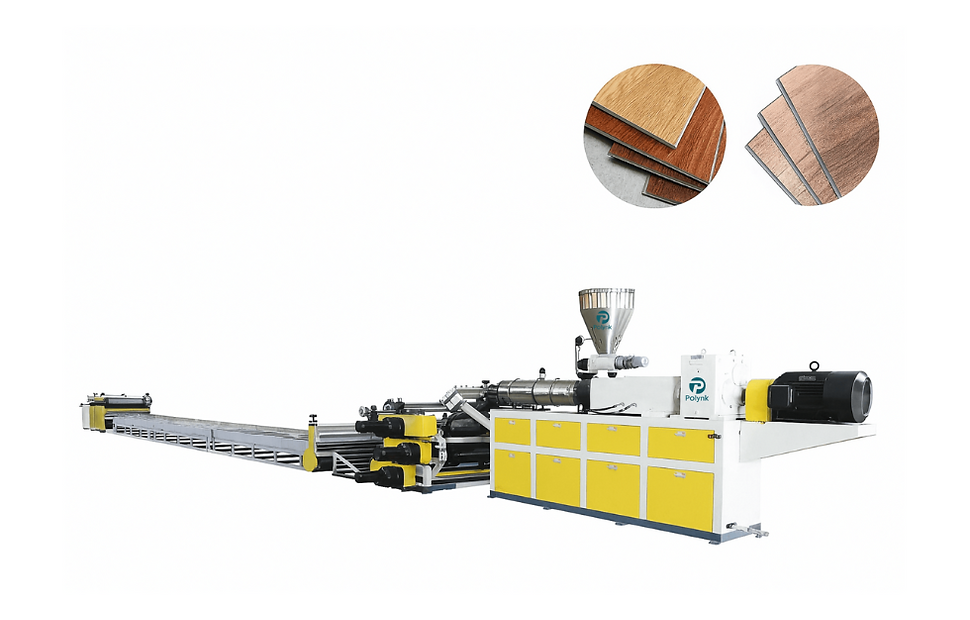

LVT Composite Floor Extrusion Line

Product Overview

OmegaPack, in partnership with Polynk (a JWELL Group brand), presents a high-performance extrusion line designed for manufacturing LVT (Luxury Vinyl Tile) composite flooring. This line offers efficient, high-speed production of flexible, multi-layer flooring panels used in residential, commercial, and hospitality projects where durability, design flexibility, and environmental safety are essential.

Utilizing polyethylene plastic and non-radioactive stone powder as core raw materials, LVT floors produced with this system are fully non-toxic, recyclable, and free from heavy metals — making them a true green flooring solution.

Applications

LVT composite flooring is widely used in:

Residential Flooring

Safe, non-toxic floors for homes and apartments, suitable for children and elderly environments.

Commercial Spaces

Durable and easy-to-maintain flooring for offices, hospitals, clinics, and schools.

Retail & Hospitality

Stylish, cost-effective floors for restaurants, showrooms, and hotels.

Healthcare & Education

Environmentally friendly flooring for hospitals, labs, and classrooms due to its hygienic and anti-bacterial properties.

Typical Structure of the LVT Floor Produced

Base Layer (PVC + Stone Powder)

Decorative Printed Film

Wear-Resistant Transparent Layer

Optional Sound-Absorbing or Anti-Slip Backing Layer

Key Benefits and Features

Feature | Description |

Eco-Friendly Composition | Made with recyclable PVC and natural stone powder — non-toxic, non-radioactive, and fully safe for indoor use. |

Multi-Layer Lamination Technology | Extrudes the flooring base, then combines it with printing film, wear layer, and backing layer in a single continuous process using a six-roller lamination unit. |

High Output & Stability | Optimized for consistent sheet thickness, smooth surface finish, and tight layer bonding without wrinkles, shrinkage, or deformation. |

Precise Temperature and Tension Control | Ensures accurate lamination, preheating, and release, improving product quality and reducing waste. |

Compact Layout & Low Maintenance | Simple operation, easy maintenance, and a production line optimized for reliability and energy efficiency. |

Process steps

Specifications

Specification | SJZ80/156 |

Material | PVC |

Product width | 1200mm |

Product thickness | 1.5-4mm |

Extruder specification | SJZ80/156 |

Roller specification | Φ400 |

Qty of rollers | 6pcs |

Capacity(Max) | 500kg/h |

Main motor power | 75kw |