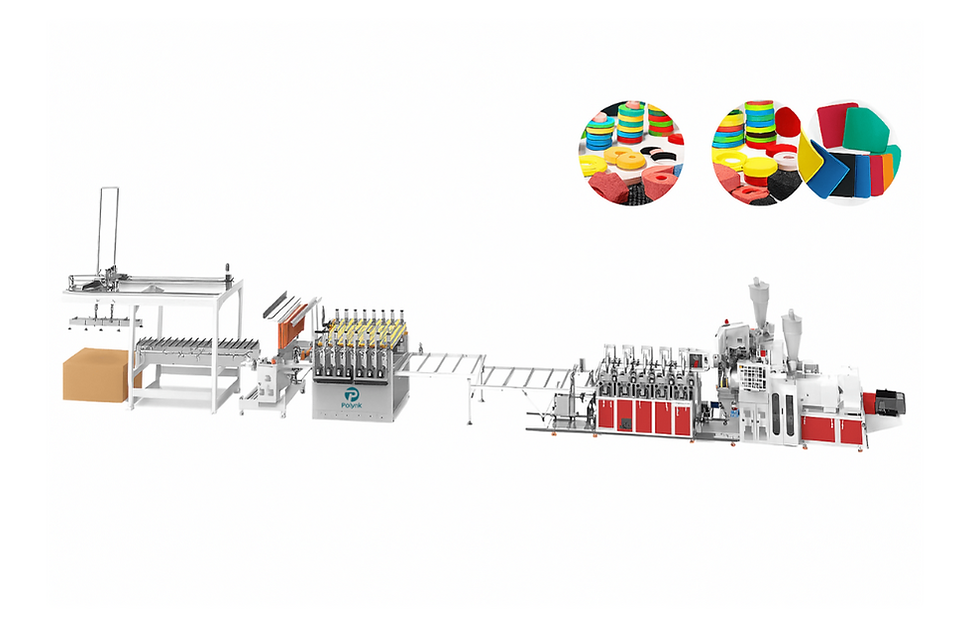

PVC Skinning (WPC) Foaming Board Extrusion Line

Product Overview

The PVC Skinning (WPC) Foaming Board Extrusion Line from Polynk, available exclusively through OmegaPack, delivers high-quality production of wood-plastic composite (WPC) foam boards. Designed to combine the aesthetic and processability of wood with the durability of plastic, this extrusion line offers an optimal balance of product surface quality, mechanical performance, and production economy.

Ideal for both interior and exterior applications, the system supports manufacturers aiming to expand into versatile WPC markets with a cost-effective, low-density foaming process and reliable skin foaming technology.

Applications

The foamed boards produced by this line are suitable for a wide variety of use cases:

Construction: Building formwork, bathroom partitions, car ceilings

Signage & Displays: Billboards, lettering boards, venue seating

Packaging: Toy building block panels, trays, turnover boxes, containers

Furniture & Interiors: Decorative panels, sunrooms, outdoor floors

Industrial & Commercial: Indicator panels, equipment housings, structural boxes

Its broad compatibility makes it ideal for producers seeking to serve construction, packaging, display, and automotive sectors.

Material and Structure

The boards are made from PVC and natural wood fiber or powder, achieving a natural wood appearance while offering enhanced durability, impact resistance, and weather tolerance.

Key Benefits and Features

Property | Value/Performance |

Surface Quality | Smooth and flat due to advanced skin foaming layer |

Density Range | Lower than crust foaming; balanced between surface quality and lightweight core |

Surface Hardness | Intermediate between free foaming and crust foaming |

Processability | Excellent – cutting, nailing, screwing, printing, and laminating supported |

Process steps

Specifications

Specification | Skinning foamingBoard extrusion line | Co-extrusion foamed board extrusion line |

Products Width | 1220–1600 mm | 1220–1600 mm |

Products Thickness | 3–30 mm | 3–30 mm |

Extruder Specification | SJZ80/156 | SJZ65/132,SJZ80/156 |

Capacity (Max) | 300–400 kg/h | 400–500 kg/h |

Main Motor Power | 75 kw | 37/75 kw |