PVC WPC Door Panel Extrusion Line

Product Overview

The PVC WPC Door Panel Extrusion Line from Polynk, offered exclusively through Omegapack, delivers reliable, high-capacity manufacturing for wood-plastic composite door panels. With a production width range from 600 mm to 1000 mm, this line is designed to meet the growing demand for large-format interior and exterior door panels with advanced mechanical and environmental properties.

Applications

This extrusion line is ideal for producing:

Interior and exterior WPC doors

Moisture-proof and flame-retardant composite doors

High-strength, lightweight PVC-based architectural panels

Large-format paneling for commercial or residential doors

System Components

The extrusion line is composed of precision-engineered machinery and automation systems.

Product Advantages

The WPC door panels produced by this line exhibit a unique combination of strength, stability, and durability:

Lightweight construction for easy handling and installation

High tensile and impact strength for lasting performance

Excellent resistance to moisture, mildew, and cracking

Flame-retardant and environmentally safe

Stable across temperature fluctuations — cold and heat resistant

Resistant to acids, alkalis, and other harsh environments

Recyclable materials support sustainable manufacturing

Broad width capacity up to 1000 mm

Specifications and Configuration Options

Omegapack offers various configurations to suit different production needs. Current models available from Polynk include:

Key Benefits and Features

Component | Description |

SJZ92/188 Conical Twin-Screw Extruder | Ensures uniform plasticization and high output |

Calibration Platform | Stabilizes the profile shape with dimensional accuracy |

Haul-Off Unit | Synchronizes line movement and maintains material tension |

Cutter | Delivers precision cutting at adjustable lengths |

Stacker | Automatically collects and organizes finished panels |

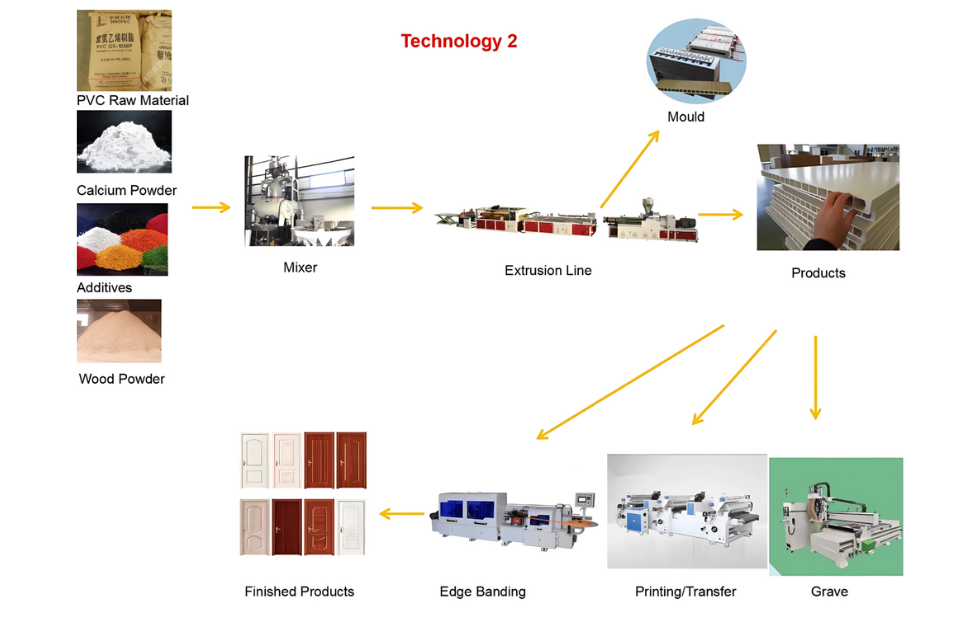

Process steps

Specifications

Specification | YF800 | YF1000 | YF1250 |

Max width | 800 mm | 1000 mm | 1250 mm |

Extruder model | SJZ80/156 | SJZ92/188 | SJZ92/188 |

Extruder power | 55 kW | 132 kW | 132 kW |

Max capacity | 250-350 kg/h | 400-600 kg/h | 400-600 kg/h |

Cooling water | 12 m³/h | 15 m³/h | 15 m³/h |

Compressed air | 0.8 m³/min | 1 m³/min | 1 m³/min |