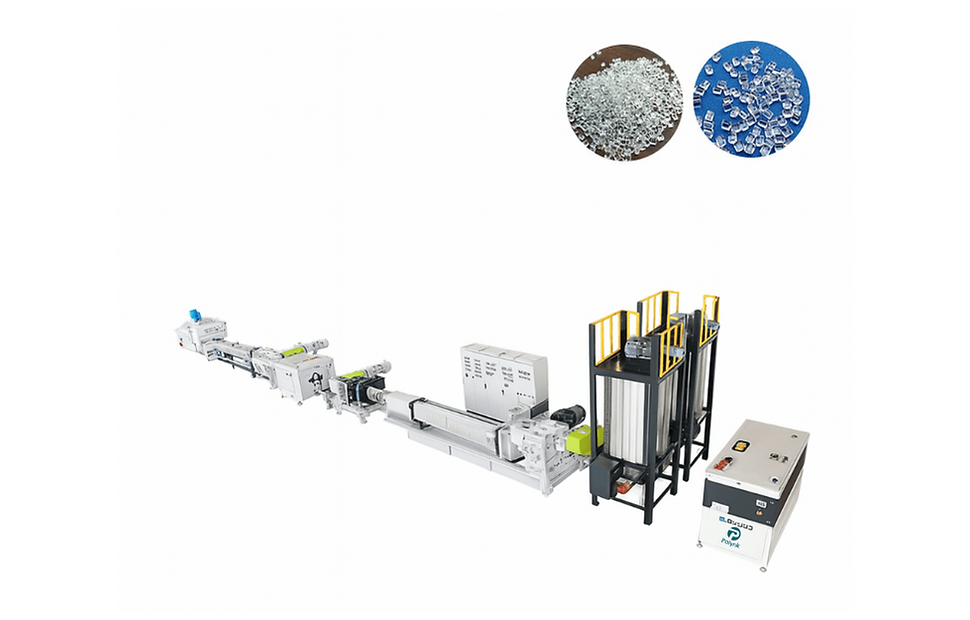

Single-Screw Pelletizing Machine

Product Overview

The Single-Screw Pelletizing Machine, offered by Polynk and distributed through OmegaPack, is engineered for efficient regeneration and granulation of various thermoplastics including polypropylene (PP), polyethylene (PE), polystyrene (PS), ABS, and polycarbonate (PC). Featuring a specially designed screw and wear-resistant barrel, this system delivers stable, high-output performance, precision mixing, and exceptional pellet quality.

Applications

Ideal for pelletizing the following materials:

PP, PE, PS, ABS and PC blends or regrind

Industrial plastic scrap from extrusion, molding, and assembly

Material recovery from production offcuts

Recycled pellets for reuse in extrusion or molding processes

System Components & Workflow

Single-Screw Extruder with precision screw/barrel pairing

Exhaust Port (Vacuum or Natural) for moisture control

Droplet Cutter or Pelletizing Head

Cooling Conveyor or Water Ring

Vibratory Separator or Screened Separator

Drying and Storage Module (optional)

This streamlined system ensures consistent pellet quality and is effective across a wide range of plastic streams.

Key Benefits and Features

Feature | Benefit |

Specialized Screw Design | Enhances melting, reduces residence time, and improves mixing efficiency |

High-Torque Gearbox | Delivers low noise operation and dependable performance |

Wear-Resistant Screw & Barrel | Extends equipment lifespan and maintains output consistency |

Vacuum or Natural Exhaust Port | Removes moisture and volatile gases for dense, stable pellet output |

High Output Capacity | Efficient production with industrial-level throughput |

Process steps

Specifications

Specification | Unit | JWL45 | JWL65 | JWL90 | JWL120 |

Screw diameter | mm | 45 | 65 | 90 | 120 |

L/D | 25-35 | 25-35 | 25-35 | 25-35 | |

Screw speed | rpm | 20-100 | 20-100 | 20-90 | 20-75 |

Power of main motor | kW | 11-15 | 30-37 | 45-55 | 75-110 |

Output | kg/h | 30-50 | 60-120 | 180-200 | 250-350 |